Equipment for Fedor Konyukhov’s successful solo RTW balloon flight in 2016 was provided by Cameron Fabric Engineering Ltd. of Bristol, UK. The equipment comprised the balloon envelope, that provided the lift necessary to carry the gondola to altitude, and the gondola which housed the pilot and operating equipment for the duration of the flight.

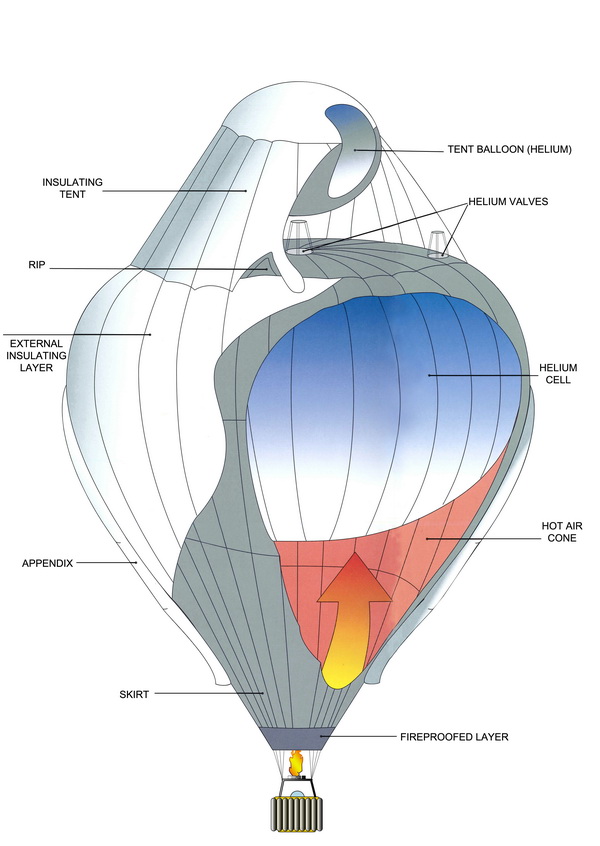

The balloon envelope was a hybrid Rozière type. A Rozière balloon has separate chambers for a non-heated lifting gas (helium) as well as a heated lifting gas (hot air). This type of aircraft takes its name from its creator, Jean-François Pilâtre de Rozier.

Rozière balloons depend for their duration on the heat of the sun by day and the heat of propane by night. At the start of the flight the main gas cell is only partly filled with helium. During the ascent decreased pressure and rising gas temperature from the heat of the sun cause the helium to expand. The system automatically vents helium gas if the pressure becomes excessive.

Overnight, as the helium in the envelope becomes cooler, the hot air burners are switched on to halt the descent of the balloon.

The advantage of a Rozière is that it allows control of buoyancy with much less use of fuel than a typical hot-air balloon. This reduction in fuel consumption has allowed Rozière balloons and their crew to achieve very long flight times of up to three weeks duration. It took Bertrand Piccard and Brian Jones 19 days, 21 hours, and 47 minutes to circumnavigate our planet in Breitling Orbiter 3 balloon in March 1999.

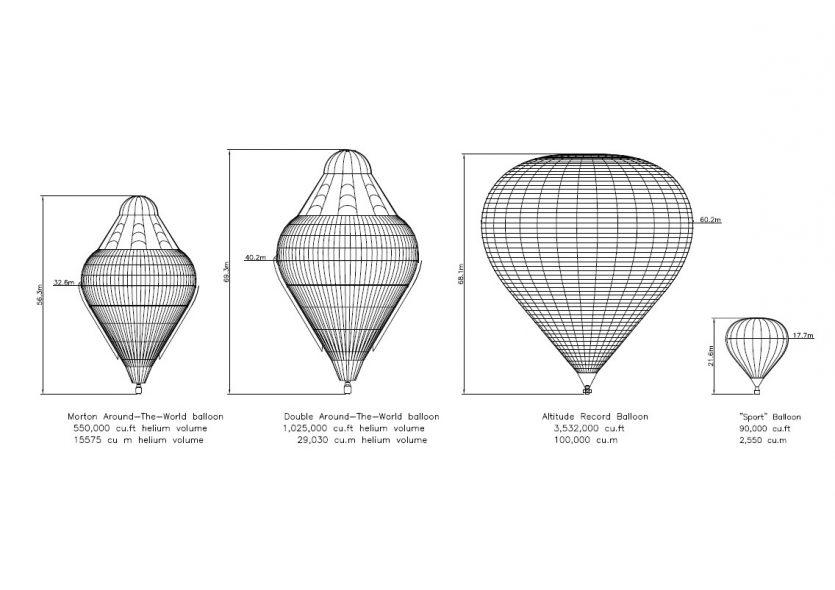

The balloon envelope for “RTW2”, is estimated to have a volume of 1,025,000 cubic feet, and the flight is expected to launch from Northam in Australia, the site used by Fedor in 2016.

The initial ceiling will be 6,000m (19,700 feet), same as the balloon Fedor piloted in 2016. However as fuel is used and ballast dropped this will increase to jet-stream altitudes of more than 11,000m (36,000 feet).

Planned fuel duration is 25 days, though with the higher winds at altitude this may be cut by up to 50%.

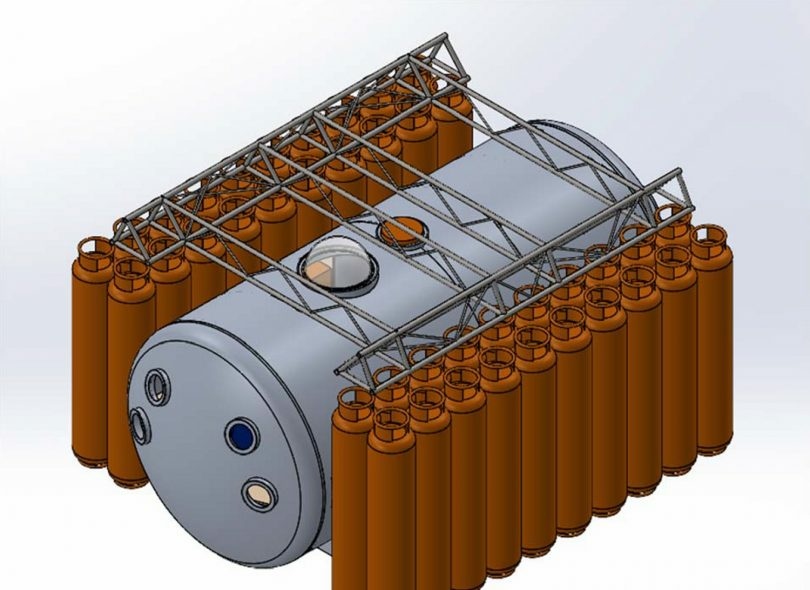

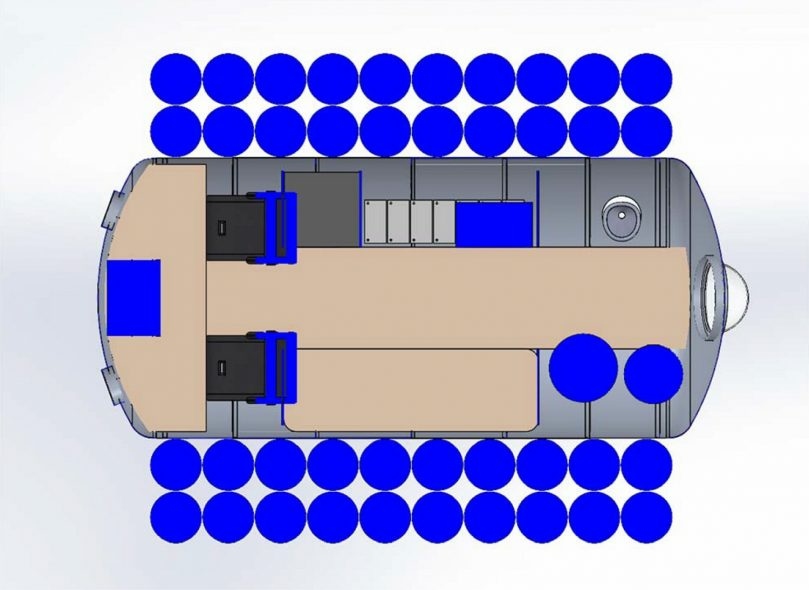

The unpressurised balloon gondola for Fedor’s RTW flight was built from composite plastic but the pressurised gondola required for this higher altitude project will be manufactured from aluminium. It will be painted a colour that will stand-out clearly both in the sky and on landing.

Inside the gondola will be a place to sleep, a heater and a facility to warm food together with storage space for food and water, clothing and survival equipment.

Communications equipment will include duplicated 720 channel VHF airband radios, HF radio, satellite telephone(s) and satellite-connection for a lap-top computer for the receipt of information in written format plus meteorological charts.

Duplicated Global Positioning Systems will be installed together with a mode S transponder with ADSB that will broadcast the position of the balloon to air traffic services.

An auto-pilot that will maintain altitude when the pilots are relaxing will be integrated.

On top of the gondola will be a low-power multi burner system powered by propane pressurised with ethane.

Specially built stainless-steel propane cylinders will be hung individually around the gondola from a metal load-frame. They will, in the main, be uncoupled and jettisoned by remote control.

Empty cylinders, designed to sink, can be jettisoned as ballast when clear of land, over the sea, and where no vessels/persons are below.

The gondola will be fitted with a re-circulating life-support system (like a spacecraft). The system will monitor the principal atmosphere components. Oxygen will be added to maintain a near constant level and scrubbers will remove exhaled carbon dioxide. HEPA and activated charcoal filters will be fitted to remove trace contaminants.

Demand and constant-flow oxygen masks will be provided for emergency use. A long hose will be provided for the constant-flow mask to allow it to be worn while performing tasks outside on the gondola roof.

The Flight Control Centre will be manned by experienced personnel who will maintain contact with the pilot 24/7 during his flight to deliver advice in respect of equipment and meteorology and will liaise with air traffic services on his behalf.